This post contains affiliate links.

Using your cutting machine can either be a fun hobby creating cool projects or an exercise in frustration that will cause you to swear worse than a sailor. When you are just learning to use your Cricut Maker, Silhouette Cameo or other cutting machines it can seem like the frustration outweighs the fun and you ruin more projects than you create.

Fortunately, many of the common cutting issues you’ll run into can be fixed with a few tweaks and making some test cuts will stop you from ruining your expensive materials. Here are the 6 most common mistakes cutter owners make and how to fix them!

Mistake #1: Not Performing Test Cuts

The best way to avoid wasting material is to do one or more small test cuts any time you’ve just inserted the blade holder and/or you’re cutting a new material. Do not assume that the recommended settings for any given material will always be accurate.

There are many factors affecting how a material will cut, including the sharpness of the blade, the condition of the mat, the intricacy of the design, the exposure to humidity, and even the color of dye used in the material.

If you cannot get a great test cut then, trust me, the rest of your project isn’t going to cut well either. It’s also a good idea to select a shape similar to what is used in your project. In other words:

- If you are cutting out a title, use a small letter as the test cut shape.

- If you are cutting out a rhinestone template, test cut a small pattern of, say, ten circles similar in size to what is used in the rhinestone design.

- If you’re cutting large simple shapes, you can use a basic shape like a circle, square, or a heart.

I developed a troubleshooting flow chart for KNK owners to use in determining the best settings. Since the basic principles behind successful cutting apply to all blade-based cutters, I recommend all owners check out this method of determining optimum settings.

Mistake #2: Blaming Bad Cuts on the Wrong Factors

Bad cuts came occur for multiple reasons so you need to determine why your cut is “bad” before you can determine how to fix it. The most extreme example of “blaming the wrong thing” is when crafters reinstall the software in an attempt to “fix a bad cut.”

That is not the solution to a cutting problem! It might be the solution if the computer and cutter are not communicating although, even in that case, reinstalling the driver should be tried first.

Here are some of the various bad cuts you may run into and some simple fixes:

| Cutting Problem | Possible Issue | Solution |

|---|---|---|

| Nothing gets cut | – force is too low | – increase cutting force |

| – not enough blade exposure | – reduce blade exposure | |

| – blade is too high above material | – lower blade | |

| – blade is chipped | – replace blade | |

| Partial cuts | – force is too low | – increase cutting force |

| – blade is too close to material | – raise blade | |

| – material is not stabilized | – check cutting mat “stickiness” | |

| – more than one pass is needed | – perform multiple passes | |

| – speed is too high | – lower speed | |

| Tearing | – too much blade exposure | – reduce blade exposure |

| – force is too high | – lower cutting force | |

| – material has been exposed to humidity | – attempt to dry material or purchase new | |

| – material is not suitable for cutting | – check manual if material and blade are compatible | |

| End point is offset from start point | – force is too high | – lower cutting force and increase number of passes |

| – speed is too high | – lower speed | |

| – material is not stabilized | – check cutting mat “stickiness” | |

| – bottom of mat is sticky | – check underside of cutting mat and remove excess adhesive | |

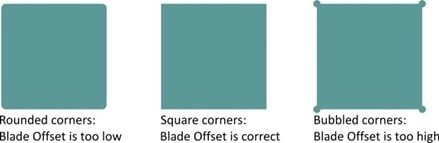

| Chads and/or rounded corners | – blade offset is too low | – increase blade offset |

| Bubbles at outer corners and/or divots in inner corners | – blade offset is too high | – decrease blade offset |

Mistake #3: Not Fully Stabilizing the material for Cutting

Stabilizing is the process of having some kind of backing to the material that is not penetrated by the blade. This backing keeps the material from being shifted by the blade and prevents cut pieces from “falling away” from the material as other parts of the project continue to be cut.

Vinyl and many iron-on products already have a backing layer that is not penetrated by the blade and will serve as the stabilizer. Paper products and fabrics, however, need to be stabilized by pressing onto a clean and sticky mat which also should not be penetrated by the blade, but only grazed by the tip.

When someone contacts me with an issue where there are certain spots not cutting cleanly (refer to the photo above) I will first ask them to check their cutting mat closely, to see if the tackiness is missing in those particular spots.

Often this happens exactly where the pinch rollers are traveling over the mat. But it can also just be a general loss of stickiness due to invisible material fibers collecting and interfering with the adhesion.

Cutting mats can be washed with warm water and little bit of soap. This process allows these fibers to be absorbed by the water and rinsed away. The adhesive that is still on the mat will not be removed and, once dry, the surface should be quite sticky again.

But check the entire surface and add more repositionable adhesive to any spots that are no longer sticky. You can also use Goo Gone or Duck Adhesive remover to completely strip a mat and then apply a new thin coat of repositionable adhesive across the entire mat. For full details check out our article How to Clean and Restick Cutting Mats.

Mistake #4: Having Too Much Blade Exposed on the Blade Holder

This is a counter-intuitive issue that first arose with the Wishblade and Craft Robo cutters ten years ago. Users couldn’t understand why increasing the blade exposure (by changing a cap color on those blade holders) didn’t resolve the cutting problems they were having.

The fact remains the same with all cutters: more blade isn’t going to provide better cutting. The amount of blade showing should be the thickness of the material plus just the least amount more possible.

If you have a lot more blade exposed, not only are you unnecessarily cutting into the mat and dulling the blade, but you’re going to see more incidences of tearing, crumpled corners and incomplete cuts.

When the blade tip extends into the mat, then upon lifting at the end of a path, it is more likely to pull the material away from the mat, thus unstabilizing it and possibly tearing it.

Note: The new KNK Force is the exception to this “rule”. Because it has depth control, the blade can be fully extended but prevented from cutting into the mat. But this is currently the only cutter with Z-axis control in the hobby cutting market.

Mistake #5: Assuming a Blade is Chipped

Blades can get chipped if the blade holder is dropped or knocked against a hard surface. On high force machines, one can also chip a blade if too much blade is exposed, along with excessive force.

The blade not only penetrates the material but is then pushed well into the mat, hitting the hard surface below. This being said, chipping doesn’t happen very often and shouldn’t be assumed when you suddenly get incomplete cuts. For one thing, most chipped blades will not cut a material at all, versus yielding a less-than-perfect cut.

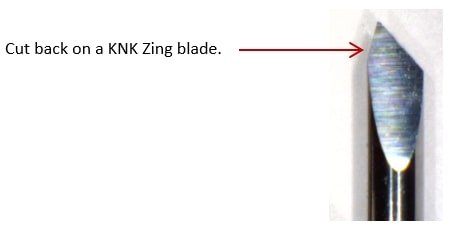

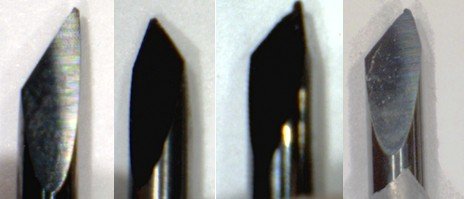

The easiest way to tell if the blade is chipped is to scan it. A scanner will magnify the image, making it much easier to examine the tip of the blade. Now, some blades have a cutback to reduce the size of the offset and allow better detail for small shapes. Don’t confuse the cutback as being a chipped blade:

The cutback on some blades looks like this (note that the tip is still very sharp):

Chipped blades look like this (note that the tips no long have a sharp point):

If your current settings are no longer yielding clean cuts, but the tips of the blade are still sharp, increase the force instead.

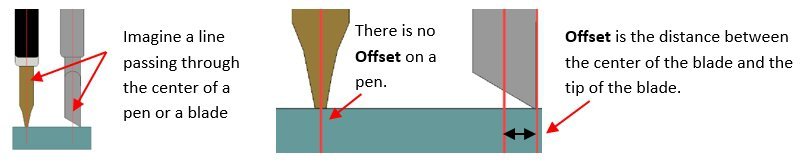

Mistake #6: Not Understanding What Blade Offset Does and Does Not Do

Some of the time, blade offset will get falsely blamed for cutting issues. Other times, it is totally missed as the cause of rounded corners, bubbled corners, or hanging chads (cut shapes that are just barely still attached to the waste material where the blade starts and stops on that shape).

So, take the time to understand what this setting does. Note that cutters with a limited range of blades will have the setting built into the firmware. But if you find this setting in your cutting software, then it’s important to understand it.

Blade offset is a correction made for the fact that the tip of the blade is in a slightly different location than the center of the blade shaft:

If the blade offset is left at 0 and a medium or large shape is cut out, the shape will still be attached to the waste. The purpose of the blade offset is to instruct the blade to travel a small distance further to ensure the cut is complete.

Entering the correct blade offset is also important on corners and valleys. The following shows how corners are cut depending on the setting used:

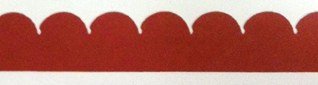

Here’s a photo of a cut sample where the blade offset was too high, causing divots in the scallop:

But blade offset is NOT the cause of inaccurate print and cuts! It also is not the reason why a shape is the wrong size or why the ending point of a cut is way off from the starting point, as in this example:

In this particular cut, either the cardstock shifted on the mat during the cut or the mat itself shifted. It was unrelated to the blade offset used.

Summary

If you found any of this information helpful, please give us some feedback and share the Pinterest friendly infographic below!

I hope this list has provided you with useful information to keep in mind. I welcome questions and feedback from all readers. Please post here or email me: sandy@iloveknk.com.

This was another great post by Sandy McCauley, the owner of I Love KNK.com! Sandy has been supporting cutter owners since 2005, when she wrote her first tutorials for the Wishblade and Craft Robo. Since that time, she has written user manuals for KNK USA and Graphtec GB, taught cutter owners at nation-wide KNK retreats, and made over 400 software videos. She answers tech support questions at various Facebook groups, Yahoo groups, and cutter forums. Sandy has helped so many people over the years and we are very happy to have her share 6 common mistakes made by cutter owners.

*In case you missed it, Sandy previously wrote about 7 learning mistakes made by Cutter Owners.