This post contains affiliate links.

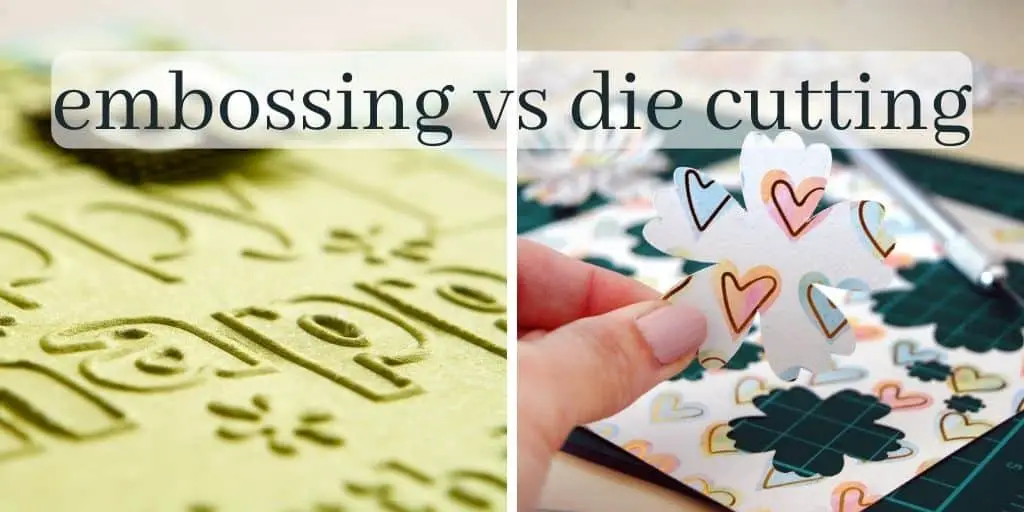

Die cutting and embossing are two techniques used in the creation of high-quality crafts, but the difference between the two can sometimes be a little confusing. While the two have some overlap, they are still distinct methods used for different purposes.

Die cutting is a high precision cutting method used to cut shapes from a material using a manual or digital die cutting machine. Embossing is a decorative technique used to raise sections of a material to provide texture to a design. It can be done using several methods, including heat, dry, and foil embossing.

That’s the simple answer, but it is more complicated than that. I’ll go into more detail about the exact differences between die cut and embossing, how they work, and what materials you can use.

The Difference Between Die Cutting and Embossing

Die cutting and embossing are often mentioned alongside each other, but they are actually used for different purposes. Die cutting is used to precisely cut shapes and intricate designs out of different materials.

Embossing on the other hand is an artistic technique. It adds a raised design, pattern or image to a material.

Both are often used together to create cards and other craft projects. Certain methods of embossing can also make use of a die cutting machine, which we’ll discuss more in the embossing section below.

What is Embossing?

Embossing refers to a technique which creates texture on a material by raising part of its surface. Most types of embossing don’t just give an illusion of texture, but instead, actually deform the material to create the texture or pattern.

Embossing could take the shape of:

- Raised lettering or numbering

- A specific pattern or picture

- General texturing or patterning across an item

Many types of materials can be embossed as long as you have the proper equipment, like paper, leather, and even metal. Whether or not you know it, you likely see embossed patterns every day.

Different Types of Embossing

There are several different types of embossing, and each has its own method and use. I’ll discuss the three most popular methods of embossing: heat embossing, dry embossing, and foil embossing.

Of these three methods, there is no “best” since it’s based on the needs of your project. Which embossing method you choose will depend on the material you are working with, your budget, and what you want the final project to look like.

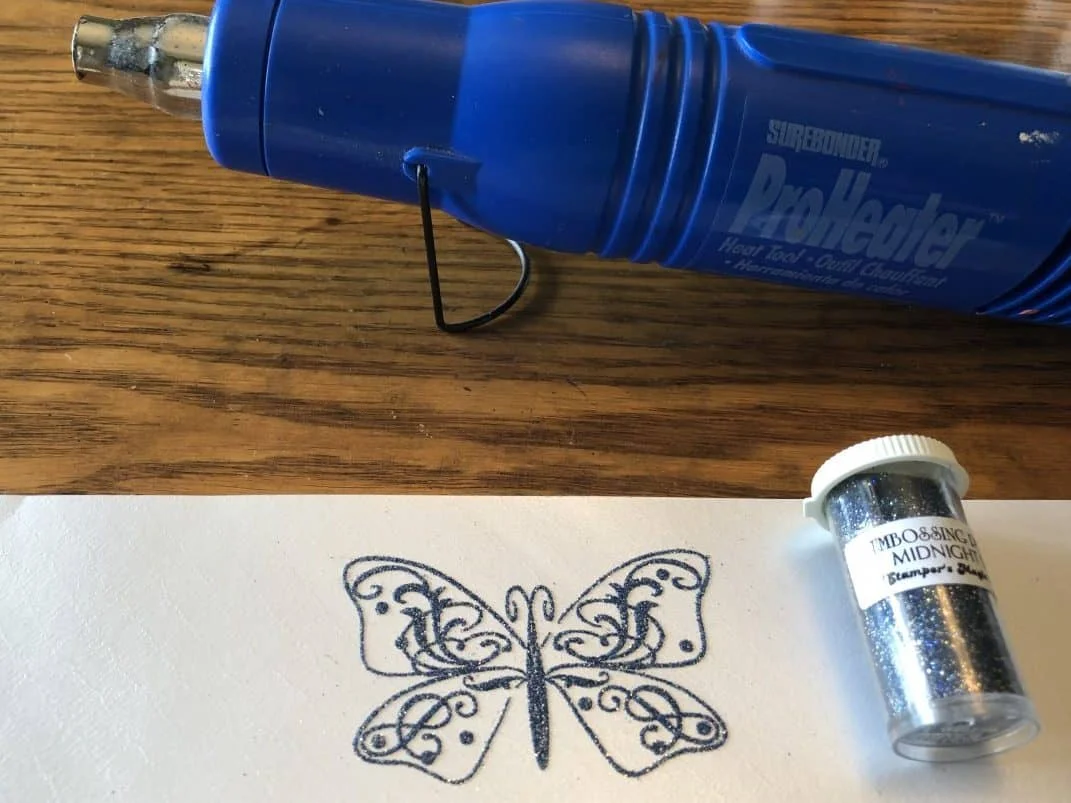

Heat Embossing

Heat embossing is a type of embossing that uses ink, embossing powder, and heat to create an image or texture on top of the material. It doesn’t physically deform the material the way dry embossing does.

This type of embossing is common, and you’ll usually see it on very high-quality stationery like wedding invitations or greeting cards.

However, it does have its limitations. Heat embossed pictures or patterns can crack if they are done on a material which will be flexing a lot.

To heat emboss, ink is applied to a material using either a special pen or a rubber stamp. Not all stamping inks will work since some dry too quickly but it also doesn’t have to be ink specific to embossing.

Embossing powder is generously sprinkled over top of the ink. The ink acts as a glue to hold the powder on your design and the excess powder is shaken off. A heat gun is used to heat the powder until it melts and forms a cohesive raised pattern on the material.

Heat embossing can be done on any material which the ink and powder will stick to since it does not rely on actually deforming the material at all, instead it just adds a raised pattern on top.

What is Embossing Powder?

Embossing powder is made from a polymer, or plastic base mixed with dyes and then finely ground. It can be mixed with things like:

- Metal powders, for a metallic finish

- Powdered colored dyes

- Larger metal flakes or other reflective bits to add a sparkling effect

These ingredients are added in different quantities to the powdered polymer base to create all sorts of different effects and colors when thoroughly mixed together to form a cohesive powder. When high heat is applied to the powder, the polymer will melt together and trap the rest of the ingredients inside, forming what is essentially a raised plastic pattern on the material.

- Lindys embossing powder colors are two toned, (with a base color and a subtle 2nd shimmery color)

- EP sets include 5, 0.5oz jars of embossing powder colors that coordinate with their spray set of the same name

- Add it to wet ink, heat it and watch it create a whole new dimension

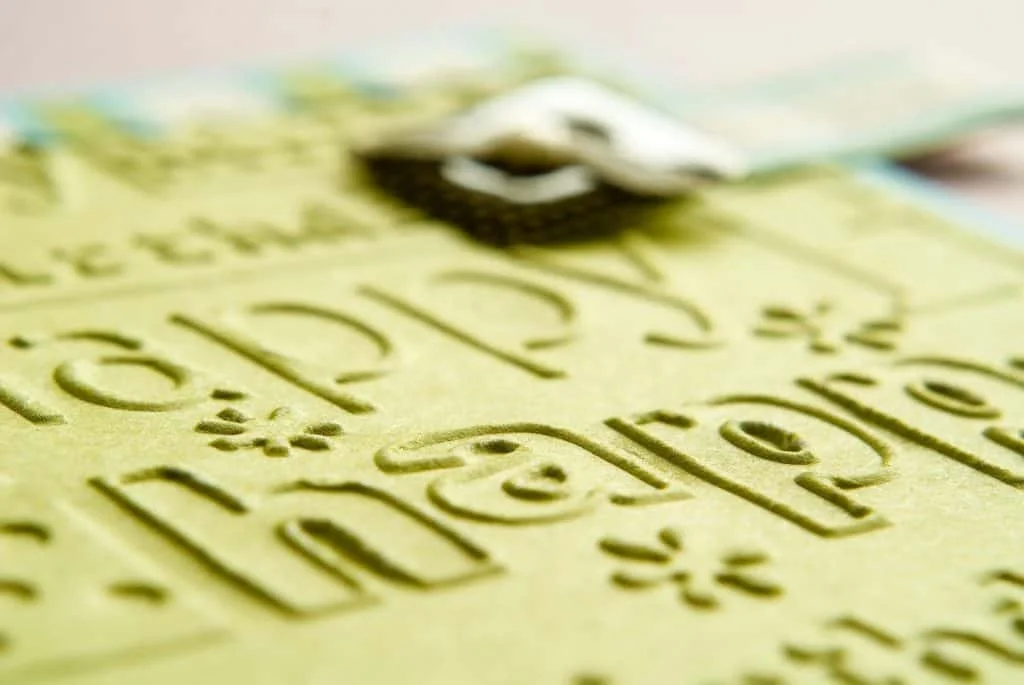

Dry Embossing

Dry embossing works by applying pressure to actually deform the material in a very specific and targeted way to create a raised pattern or image. This is also sometimes called relief embossing or pressure embossing.

It can be done several ways including manually by hand, using a manual die cutting machine, using an embossing machine or using a digital die cutting machine

To dry emboss by hand you’ll need three things:

- A stencil of the pattern which you want to emboss

- A lightbox to aid in tracing the stencil pattern (optional, a sunny window will work as well)

- A dull stylus to apply pressure

The stencil is placed above the lightbox, then the material is placed on top. The stylus is then used to trace the stencil’s pattern while applying firm, steady pressure. The material is forced down into the empty spaces in the stencil, which creates the embossed pattern.

Unfortunately, this only works on materials which are thick enough to not tear or break but still thin enough that you can apply enough pressure by hand for your image to emboss properly

However, for stronger materials, or for a crisper emboss, you can use a machine to help. Manual die cutting machines can be used for embossing. There are also embossing specific machines. The principle behind embossing with a machine, whether a die cutting or embossing machine, is the same.

Machine embossing uses two embossing dies: one with a raised pattern (called a male die) and one with a lowered matching pattern (called a female die). The material is sandwiched between the two and is rolled through the machine.

The machine applies far greater pressure than anyone could do with their bare hands. This forces the material to be deformed into the shape of the patterns on the dies, creating the raised embossed image.

Using a machine to dry emboss is much faster and more precise than dry embossing by hand. But it does come with a larger upfront cost.

You’ll need to purchase the machine and embossing dies or folders. If you just need something embossed for a single project or two, it’s more economical to stick to relief embossing by hand.

You can also dry emboss using a digital die cutting machine but it’s a much more complicated process. See my article How to Emboss with the Cricut Explore Air 2 for more information.

Otherwise, it’s very easy to deboss with a digital die cutting machine like the Cricut Maker and it’s Debossing Tip. Debossing is the opposite of embossing in that it leaves a depression in the material.

Foil Embossing

Foil embossing refers more to a style of embossing rather than a single method. The end product of foil embossing is a raised pattern which is also covered in a metallic foil.

It makes it look like a 3D metal object has been placed on top of the material. Methods for foil embossing can range from the simplest DIY home method to industrial foil pressing machines which cost tens of thousands of dollars.

At its simplest, a thin metal foil is adhered to the material using a traditional strong bond adhesive. The material is then dry embossed normally, with the adhered foil embossing along with the base material. More in depth methods involve the use of heat to soften and adhere the foil, and the foil can often be added at the same time as the embossing is taking place.

What is an Embossing Die?

If you want to dry emboss with a machine, then you’ll need a set of embossing dies. These are specially formed dies with two parts:

- The raised, or male, die is a piece of metal or other material which has been specifically machined to have the pattern which is going to be embossed.

- The lowered, or female, die is a matching piece of metal or other material which instead has the pattern recessed into it

When the two dies are pressed together, they sandwich perfectly. You can think of it like placing a tortilla on top of an upside-down bowl, then pushing another bowl down on top. The bottom bowl is the female die and the top bowl is the male die. When the material (tortilla, in this case) is sandwiched between them, it takes on a raised bowl shape.

There are also embossing folders, which are commonly used alongside die cut machines. They consist of a folder which has the male die on one flap and the female die on the other flap.

The material is sandwiched between the two and then run through a die cut machine which applies the pressure necessary to deform the material between the two flaps of the folder. This results in an easy, quick, and affordable way to emboss materials at home.

What is Die Cutting?

Die cutting is a method of cutting material into precise shapes by applying force to a die. A die is like a cookie cutter, it is a sharp metal tool in a specific shape.

It uses either a manual or digital die cutting machine to cut the shape from the material. Die cutting is used when you need a very detailed shape cut, a large quantity of shapes cut or both.

For manual machines, you first need a cutting die. The cutting die is the blade that actually cuts the material and the machine applies pressure to the die to force it to cut through the material.

Here’s the basic steps of using a manual die cutting machine:

- The material to be cut is placed on top of the cutting plate, which is a sturdy piece of plastic that acts as a solid base for the process.

- The cutting die is positioned on top of the material and aligned where it needs to be cut

- Another cutting pad is placed on top, completing the die cut “sandwich.” The plates ensure even pressure is applied when cutting.

- The sandwich is rolled through the manual machine, which applies force causing the die to cut through the material

To learn more about using a manual die cutting machine see my article, How To Use Metal Die Cuts: The Complete Guide

Digital die cutting machines, however, work differently. An image is designed or uploaded into the die cutting machine’s software, it is then sent to the machine where a sharp blade cuts the image out of the selected material.

Digital die cutting machines can cut nearly any shape, image or design you can think of. The top brands, Silhouette and Cricut, both have their own proprietary software which you need to use to send your project to your machine.

What Are Cutting Dies?

If you will be using a manual die cutting machine, then you are going to need a set of cutting dies. They are basically a sharp piece of metal which is designed in a specific shape—think like a cookie cutter. The material your cutting dies are made of will depend on the type of material you’ll be cutting. Thicker and tougher materials necessitate the use of tough, strong steel dies.

Cutting dies come in an extremely wide variety of shapes and sizes, from simple shapes like squares to complex shapes like flowers and spirals. They can even be nested to create unique designs. Just make sure the dies you are using are both suited to your machine and the material you’ll be cutting.

- 【Package Includes】: 2 Sets Round Shape, 1 Set Square Shape, 1 Set Rectangle Shape, 1 Set Heart Shape, 1 Set Flower Shape, 1pc clear plastic box; Different Shape for...

- 【Good Quality】: Premium Material - made of carbon steel, highly detailed and delicate; Good Workmanship - with a smooth edge line, safe to touch

- 【Wide Usage】: Great for Scrapbooking, Paper Card, Embossing, Album, Card Stock, DIY Craft. Excellent for cropping photos precisely, they are also great for making...

What is Debossing?

Debossing is a technique which creates texture on a material by lowering part of its surface. It is essentially the reverse of embossing. If something is embossed then it is raised from the material like a mountain, if it is debossed then it is lowered like a valley.

To deboss with a manual die cutting machine you just need to place your material between the embossing folder upside down, which will result in a debossed (lowered) pattern.

Some digital machines are starting to have the ability to deboss. The Cricut Maker has a debossing tip which can be used to make clear, crisp debossed patterns by using a rolling steel ball.

Digital machines offer a lot more flexibility than a static embossing/debossing folder. However, these tips can only offer a single level emboss or deboss, as opposed to multilayered or multitextured patterns that can be achieved with manual debossing.

What Materials Can I Emboss?

The types of materials you can emboss is very dependant on the method of embossing you are using. Some materials like cardstock can be foil, heat or dry embossed very easily, while others will have limitations.

What Materials Can I Heat Emboss?

Heat embossing can be done on any material which the ink and powder will stick to. If the material is going to be flexed a lot then heat embossing may not be the best option as the hardened powder can crack.

Additionally, a material that will melt under high heat is not a good choice, since it will likely deform while heating the embossing powder.

Common heat embossed materials include:

- Paper products, including cardstock and linen paper

- Acrylics or other hard plastics

- Leathers of varying thicknesses

What Materials Can I Dry Emboss?

Dry embossing is limited to materials that can be easily deformed under pressure. It will also depend on whether you are using a machine to emboss or are embossing by hand.

If you are dry embossing by hand, you will be limited to materials that aren’t too tough because you have to be able to apply enough pressure by hand to get a good impression. This mostly limits you to embossing things like:

- Paper products, especially cardstock

- Soft plastics like vinyl

- Flexible leathers (wetting the leather beforehand helps)

If you are using a machine and embossing dies or folders, then you have more options since the machine can apply a lot of pressure. Depending on the capabilities of your machine, you could emboss:

- All types of papers

- Felts and other fabrics

- Leathers

- Plastics

- Varying thicknesses of metal and metal foils

Final Thoughts

Die cutting and embossing both have their specific uses in the crafting world. Die cutting is a way to cut precises and intricate design while embossing adds raised textures or images to a material. They work well together to create interesting and unique projects.

If you are ready to jump into the world of die cutting and embossing, check out my articles Best Die Cutting Machines for Beginners as well as An Introduction to Die Cutting.